In yet another similar case, the vibration levels despite controlling the oil-inlet temperature and pressure did not come down to safe limits. Obviously, the problem was arising of too-less clearance between the bearing and the shaft. As mentioned, the oil-whirl problem arises when the load to be supported by the oil film is less than the vertical component of the pressure of the hydrodynamic film of lubrication.

Since the problem could not be sorted out by manipulating the oil-inlet temperature and pressure, a deliberate unbalance was put on the shaft so that the bearing load increases. With this, though the vibration levels in the other non-whirling bearings increased to a certain extent, all the bearing-vibration levels came within the acceptable range.

Many a times, a deliberate misalignment in the neighbouring shafts, solves the oil-whirl problem. Nevertheless, it should be borne in mind that the measures such as deliberate unbalance or misalignment and so on, provide only a symptomatic relief. The correct solution is to provide only a correctly designed bearing.

A whirling bearing in a multi-rotor-bearing system can cause damages to other bearings too. Keeping this in mind and also the fact that whirling bearing will be subjected to rapid wear out, it is not advisable to neglect the oil-whirl problem.

Contrary to the phenomenon of the oil whirl, the friction-related whirl, also called the shaft whirl occurs due to the physical contact between the bearing liner and the journal. This can wipe out of the bearing. Here, when the contact takes place, the frictional force at the point of contact drags the rotor up (Fig. 7.41) and a fresh contact is made. At this point, it is again thrown to another position. Normally, a rotor which operates above the first critical, will tend to deflect or bow in a direction opposite the unbalance / heavy spot. As a result, the internal friction-damping factor, which normally works to restrict the deflection, will be out of phase and thus will further deflect the rotor. This is generally kept in check by the damping provided in the bearings. If this damping is low due to an improper bearing lubrication, the friction excites the whirl. This whirl will always occur at a frequency equal to the first critical speed.

Many tests performed on hydro machines and large pumps have shown that the hydrodynamic bearings are lubricated with not just oil alone but a mixture of oil and air, which is present in the form of stable suspension. The air bubbles are usually quite clearly visible and comparable in diameter to the thickness of the oil film. At times, the diameter may exceed the thickness of the oil film. The degree of saturation of the oil with air in thrust bearings depends upon (a) the discharge of oil from the bearing, (b) the turbulence at the surface of the oil tank, (c) foam at the surface due to agitation of the oil caused by the obstruction in its oil path (oil coolers, baffles). The foaming sharply increases in presence of even a small amount of water (which can find its way in the system through several ways). This can cause a direct contact between the bearing and thrust collar giving rise to vibration and bearing-wipe problem.

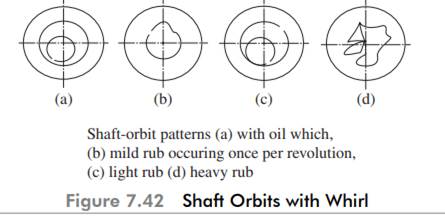

Figure 7.42 shows the shaft orbits when oil whirl and shaft whirl takes place. In fact, shaft orbits can detect not only the bearing rubs but the rubs between the rotating and stationary components in the rotating machinery. The rubs at bearings are identifiable through the vibration frequency close to the first critical while other rubs are identified through sub-harmonics and super-harmonics depending upon the degree and location of the rub.